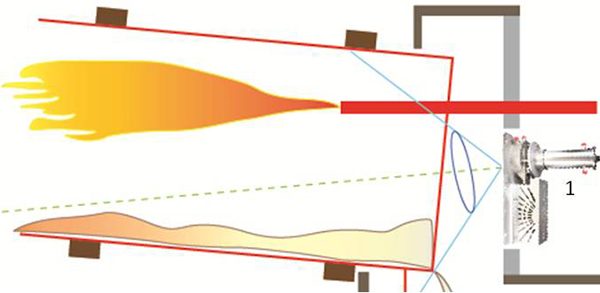

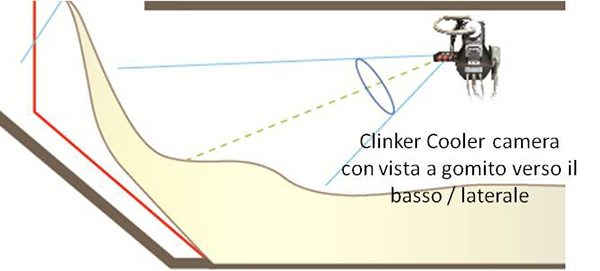

The main critical points of the process can be controlled using the Telea Tecnovision’s high temperature cameras. The visual control of the burner flames, as well as the supervision of the material formation before its entrance in the grid are fundamental.

It is also typical necessity for a cement factory to hold in check the remote points of activity: to compensate the problem of the distance, Telea Tecnovision is able to realize solutions based on optical fibre, IP networks and radio frequency transmission.

- Home

- Sectors

- Products

- News

- New CAMTEC 21X

- New INTEC release for Sondatec P

- New Zoom High Performance Camera

- New high temperature camera WIDE lens

- New high temperature portable system “S” series

- New IRScan PTZ Controller

- New IP network desktop paging console

- New heavy duty stainless steel PTZ unit

- New integrated PTZ for Thermal imaging camera

- Galaxy server with integrated Touch Station

- Who we are

- Partner

- HIGH TEMPERATURE CAMERAS

- Contacts

- Vision system up to 2200°C

- Protection devices & control cabinets

- Vision systems up to 1800°C/1600°C

- Vision system up to 400°C

- Vision system up to 250°C/90°C

- CAMTEC – IP type

- CAMTEC – Analog type

- SONDATEC

- OUTEC

- INTEC

- CABTEC

- CAMTEC “S”

- SONDATEC “S”

- CAMTEC “K”

- SONDATEC “K”

- ACQUATEC

- CAMTEC “H”

- SONDATEC “H”

- AIRTEC

- Interconnection kit – KITEC